Modularize Flux Spraying system

Modularize Flux Spraying system

Modularize Flux Spraying system

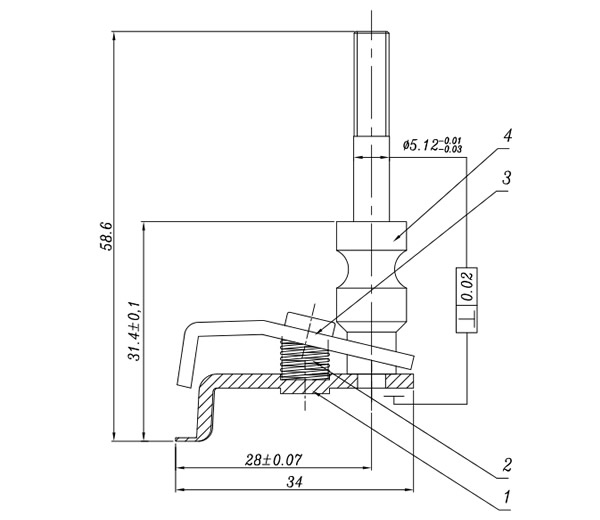

● The flux nozzle uses a stepper motor drive, which can flux coating.

● better temperature uniformity.

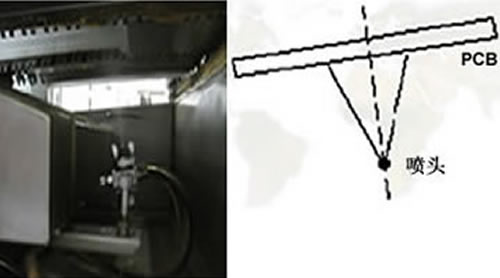

● The spray system of modular design, the nozzle is always vertical guide rail, ensure good penetration of PCB flux.

Flux spraying is perpendicular to the PCB

● Spread more even on PCB.

● Enhance flux penetrating property to the holes.

● Improve the adhesiveness of the solder metal.

● Effectively reduce the customer’s operating cost.

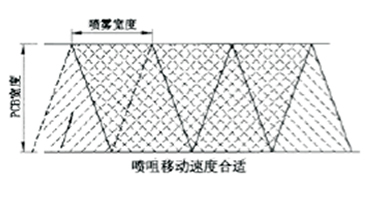

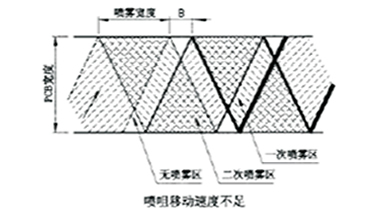

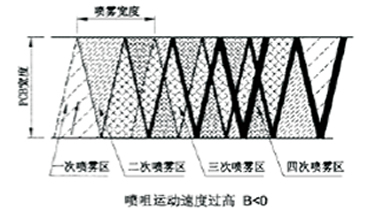

Software will optimize the path to guarantee the flux coating uniformity

Suitable Nozzle speed Spreading evenly

Nozzle speed too low. spreading did not cover all

Nozzle speed too high. Introduce spreading overlap

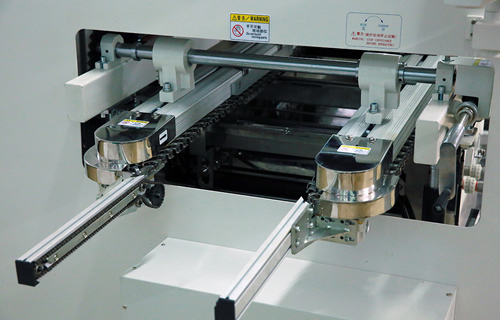

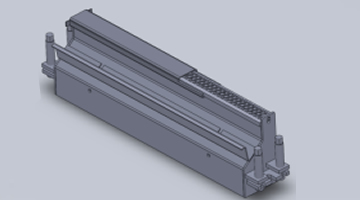

Transportation System

Transportation System

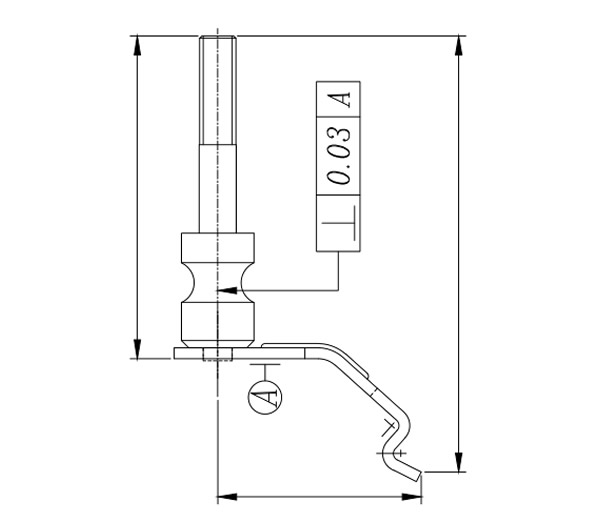

● Standard heavy double hook titanium finger can bearing over 60kg PCBA of pallets.

● The transportation system adopts floating structure, new type support profile, good strength, patent aluminum rails, and provide longer service life.

Ti Fingers

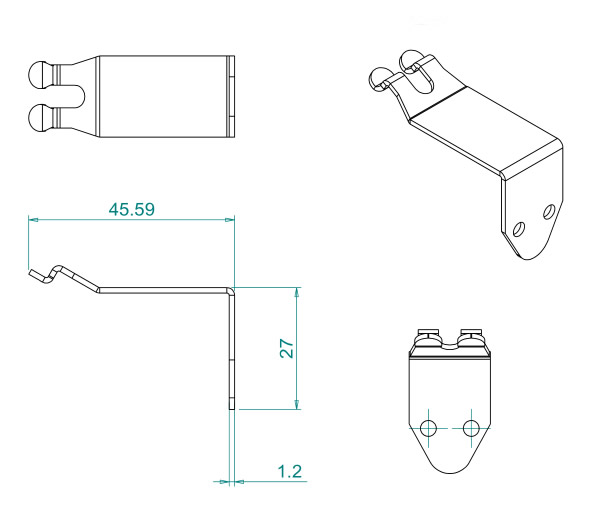

| Description | Photos | Drawing | Material | Thickness | Siutable for PCB | Suitable for Pallet | Applicable Models |

| V Type |  |

|

Fully Titanium | 1.2mm | ● | eWA Series M Series E400 |

|

| L Type |  |

|

Fully Titanium | 1.2mm | ● | eWA Series M Series E400 |

|

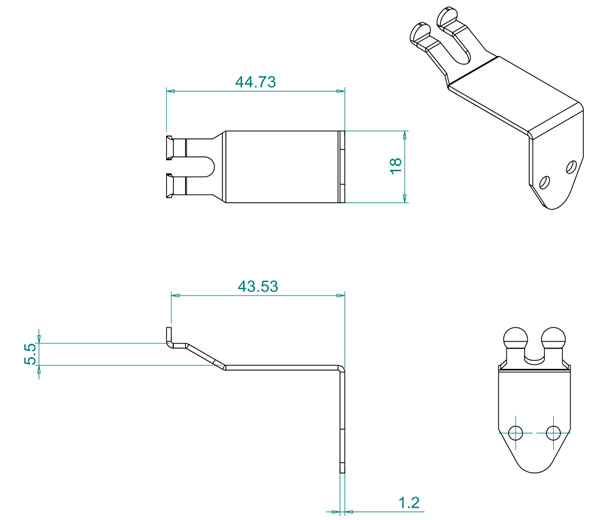

| Double Hook V Finger |  |

|

Fully Titanium | 1.5mm | ● | ● | eWA Series |

| Spring Pessed Finger |  |

|

Fully Titanium | 5mm | ● | eWA Series | |

| Heavy Load Finger |  |

|

Fully Titanium | 5mm | ● | eWA Series |

Preheating System

Preheating System

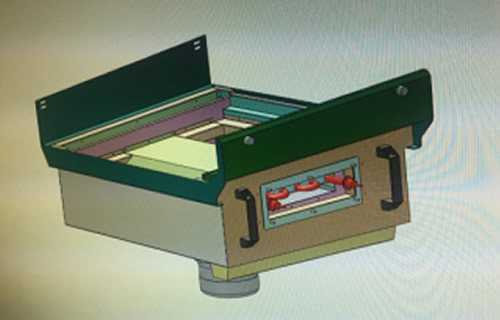

Modularize preheating system

● Plug in and remove connector easily.

● Drawer type structure that easy to install or disassemble to maintain.

● All hot air modules are for better temperature uniformity.

● For standard, only lower part have heating modules and upper part is an option.

Solder Pot

Solder Pot

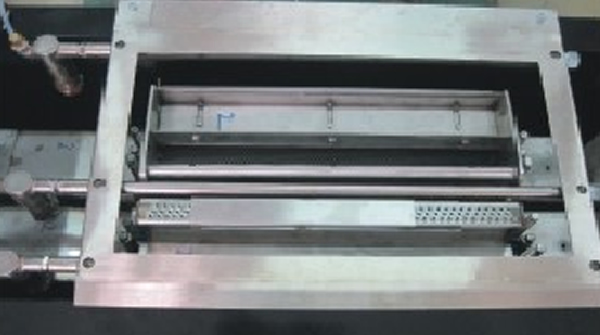

10mm thickness casting iron solder pot

● No easy to deform when heating.

● Well contact with heater for more uniform heating.

Used graphite for insolation

● anti-moisture and anti-corrosion.

Ceramic coating

● smoother surface, anti-corrosion, longer lifetime.

Insolation and large solder pot

● reduces heat loss.

● make the solder temperature to be more uniform.

● improves the solder pot heat storage capability.

Cost saved by better utilization

● The oxidation reducing cover effectively control the wave flowing speed, lower the falling height and eliminate oxide.

Solder residue should be removed everyday

Partial nitrogen charging device for solder pot

● Stainless steel porous pipe sprays nitrogen evenly and stably.

● Nitrogen will be blocked below the PCB and from a low oxygen layer between the PCB and the solder pot surface in order to achieve high welding quality and low oxidation.

● Since it is not closed area, oxygen analyzer cannot be installed

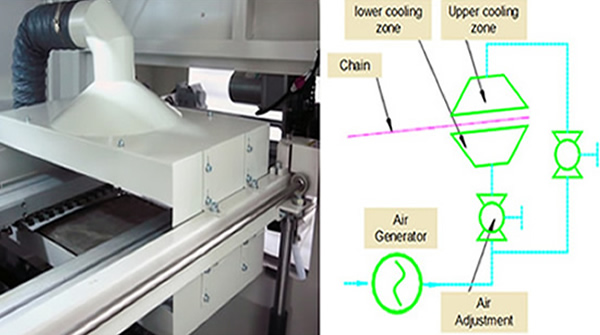

Cooling System

Cooling System

Air cooling from up and down

● Forced air cooling system, can meet lead-free work art of cooling slope requirement.